Overview of DIAMIRON™ MF Type P4

A polylactic acid (PLA) multi-layered film

A polylactic acid (PLA) multi-layered film

PLA is a plant-derived plastic.

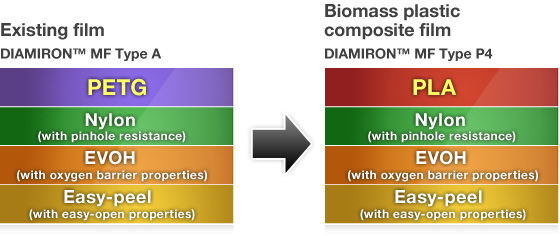

Composition

Features

1 The biomass plastic composite film's rigidity provides excellent curling properties.

-

- Existing film: A453 (80 µm)

- Existing film: A453 (80 µm)

-

- Biomass plastic composite film: Type P4 (80 µm)

| Content: | 40 grams of sliced ham |

|---|---|

| Cover material: | OPP (30 µm) / VMPET (12 µm) / EVA (40 µm) |

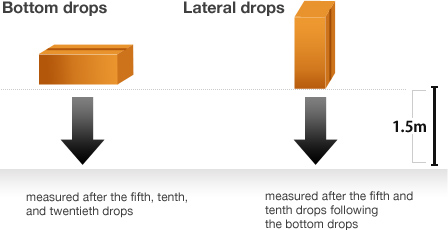

2 Comparable with existing films in pinhole resistance

We conducted a drop test with an actual package under severe conditions to observe the state of the package.

[Test description]

A cardboard box packed with 10 sets of three packages (each containing 80 grams of sliced ham) with a deep-drawing depth of 10 mm, was dropped from the height of 1.5 meters after 24-hour conservation at an atmospheric temperature of 5℃.

| Number of packages with pinholes according to the number of drops | ||||||||

|---|---|---|---|---|---|---|---|---|

| Film Type | Grade | Total thickness (µm) |

Bottom drops | Lateral drops | Total | |||

| 5 | 10 | 20 | 5 | 10 | ||||

| Conventional film | A453 | 80 | 0 | 0 | 0 | 0 | 0 | 0 out of 30 packages |

| Biomass plastic composite film | Type P4 | 80 | 0 | 0 | 0 | 0 | 0 | 0 out of 30 packages |

Notes on Type P4

- The PLA has weak heat resistance with a glass transition point (Tg) of 60℃. The sealing process may leave a rubber packing mark. (PETG has a Tg point of 80℃.)

- Folding of the film at an acute angle may leave a mark but it has no impact on the film quality.

- You may notice a smell specific to PLA at the time of deep-draw packaging (sealing).

- At ambient temperatures, very little hydrolysis occurs. However, we use the precaution of delivering the film in a moisture-proof package (moisture-proof paper pipe or aluminum package).

- Store the film in a cool dark place and avoid leaving it unpackaged to prevent moisture absorption.

- The film quality is guaranteed for a period of six months after shipment.